Introduction

In industries where equipment reliability directly impacts productivity, maintenance strategies play a critical role. Traditional preventive maintenance has long been the go-to approach—replacing or servicing components based on time intervals. But today, industries are shifting towards a smarter and more cost-effective strategy: Condition Monitoring (CM).

Condition Monitoring goes beyond scheduled maintenance. It continuously tracks the actual health and performance of machinery, enabling early fault detection, reduced downtime, and optimized maintenance costs. For industries like oil & gas, power, manufacturing, marine, and infrastructure, Condition Monitoring is proving to be a game-changer.

What is Condition Monitoring?

Condition Monitoring is the process of tracking and analyzing equipment parameters such as vibration, temperature, pressure, oil quality, and acoustics. Using advanced sensors and diagnostic tools, it provides real-time insights into machine health.

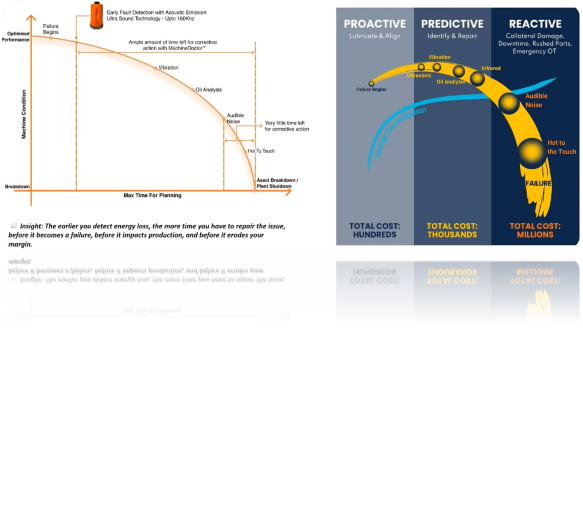

Instead of following a rigid calendar, maintenance teams can now make data-driven decisions—servicing only when necessary. This predictive approach reduces unnecessary overhauls, prevents catastrophic failures, and extends equipment life.

Why Condition Monitoring is Transforming Maintenance

1. Early Fault Detection

By identifying abnormalities like unusual vibrations, overheating, or lubrication issues, Condition Monitoring helps detect problems before they escalate into costly breakdowns.

2. Reduced Downtime

Unplanned shutdowns are expensive and disruptive. Condition Monitoring ensures planned interventions, minimizing production losses and maximizing uptime.

3. Cost Savings

Optimized maintenance schedules reduce spare parts consumption, labor hours, and repair expenses—making operations more efficient and profitable.

4. Enhanced Safety

Faulty equipment can pose significant risks to workers. By continuously monitoring asset health, companies ensure safer working environments.

5. Extended Asset Life

Consistently maintaining machinery based on its condition extends operational lifespan and delays the need for costly replacements.

Key Techniques in Condition Monitoring

Condition Monitoring uses multiple techniques depending on the type of equipment and industry requirements:

- Vibration Analysis – Detects imbalance, misalignment, and bearing faults.

- Ultrasonic Testing – Detects leaks, electrical discharges, and friction issues.

- Thermography – Uses infrared imaging to identify overheating components.

- Oil Analysis – Checks lubrication quality, contamination, and wear particles.

- Motor Current Analysis – Identifies electrical imbalances and motor faults.

Combining these techniques offers a comprehensive picture of equipment health.

Condition Monitoring vs. Traditional Predictive Maintenance

| Aspect | Preventive Maintenance | Condition Monitoring |

| Approach | Time-based (scheduled) | Data-driven (real-time) |

| Equipment Health | Not always considered | Continuously tracked |

| Costs | Higher (over-maintenance, unnecessary part replacements) | Optimized (service only when needed) |

| Downtime | Risk of unplanned failures | Predictable, minimized downtime |

| Asset Life | Average | Extended lifespan |

Clearly, Condition Monitoring offers a smarter, more proactive strategy compared to traditional maintenance.

Real-World Applications

- Power Plants: Monitoring turbines, pumps, and generators to ensure uninterrupted energy supply.

- Oil & Gas: Tracking compressors, drilling rigs, and pipelines to avoid costly failures.

- Manufacturing: Ensuring smooth operation of motors, gearboxes, and conveyor systems.

- Marine Industry: Protecting ship engines and propulsion systems from unexpected breakdowns.

- Infrastructure Projects: Monitoring construction machinery to keep projects on schedule.

The Future of Maintenance

With the rise of Industry 4.0 and IoT, Condition Monitoring is becoming smarter than ever. Cloud-based platforms, AI-driven analytics, and wireless sensors are making it easier to collect and interpret machine data in real time.

Companies investing in Condition Monitoring today are not only saving on costs but also preparing for a future where predictive maintenance becomes the norm.

Conclusion

Condition Monitoring is no longer just an option—it’s a necessity for industries striving for efficiency, reliability, and safety. By enabling early fault detection, reducing downtime, and extending asset life, it has redefined preventive maintenance strategies worldwide.

At Abizer India Innovations Pvt. Ltd. (AIIPL), we provide advanced Condition Monitoring and Vibration Analysis solutions tailored for industries like Oil & Gas, Power, Marine, and Infrastructure. With our expertise, businesses can shift from reactive maintenance to predictive strategies—achieving higher productivity and lower operational costs.