How we look after machinery is very similar to how we look after ourselves. Just like in the human body, machines give off lots of signs as their condition and performance deteriorates. We all become the subject of condition monitoring when we go to the doctor for a health check. The recording of blood pressure, weight, lung capacity etc are all designed to keep our bodies healthy by spotting any problems early.

Similarly, by using various process parameters (e.g. pressure, temperature, vibration, flow) and material samples (e.g. oil) to monitor conditions in machines, we can measure equipment health, performance, integrity and strength to schedule timely corrective action.

We provide innovative products and services in the field of proactive and predictive maintenance.

Tools and Techniques

At ‘AIIPL’, we have the expertise and resources required to implement cost-effective condition monitoring programmes that help organisations of all sizes reduce downtime, increase machine productivity and eliminate repair costs caused by unexpected breakdowns. Generally, condition monitoring techniques are used on a variety of assets such as pumps, electric motors, internal combustion engines, gearboxes, fans, electrical control panels, compressed air and hydraulic systems etc.

We enable our clients to actively prevent breakdowns, reduce maintenance costs, extend machine life and spare parts consumption while saving energy and the environment. We help in assessing the health of plant equipment by periodic monitoring, trending, and advanced analysis using Vibration Analysis, Thermography and Ultrasound Inspection Analysis techniques.

AIIPL is covering below part of Condition Monitoring Services.

- Vibration Analysis

- Thermography

- Ultrasound Analysis

- Field Balancing

- Laser Alignment

- Motor Current Analysis

- Partial Discharge (PD) Testing

- Oil Analysis

Benefits of our Condition Monitoring Services Include:

- Reduce Unplanned Shutdown

- Extend Machine Life

- Right Maintenance Decision at Right Time

- Improve the Safety & Reliability of the Machine

- Energy Saving

- Visibility of equipment condition

- Proactive trouble shooting

- Fast reaction & Reduced downtime

Technologies for using Condition Monitoring

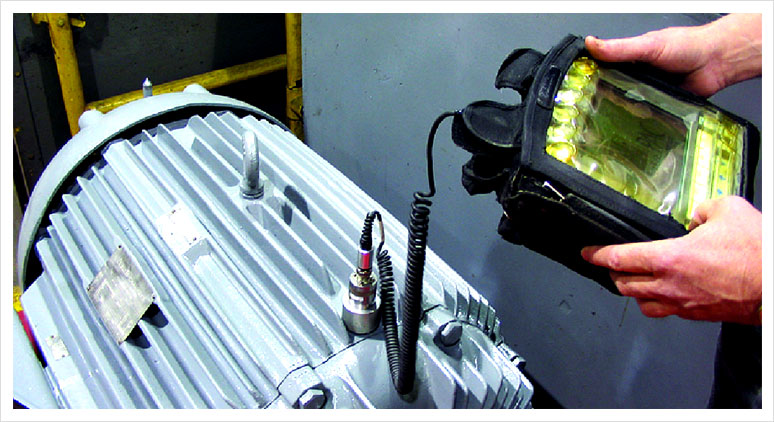

Vibration Analysis

Determines the rotating machinery health condition under various operating conditions by evaluating mechanical vibration. A change in vibration amplitude at specific frequencies can indicate a change in machine health condition.

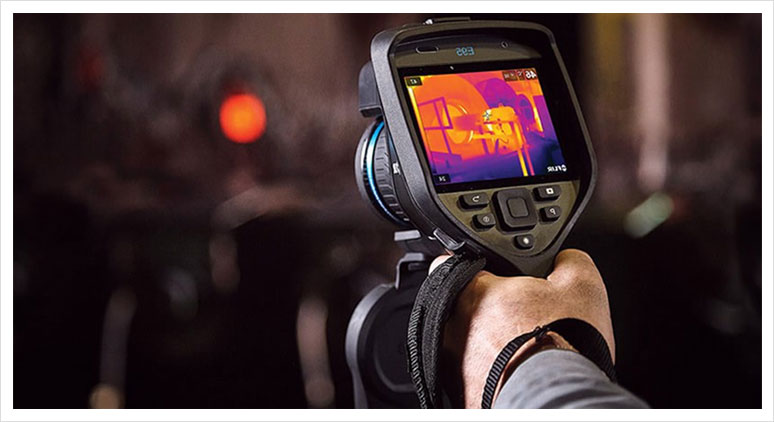

Thermography

Ultrasound Analysis

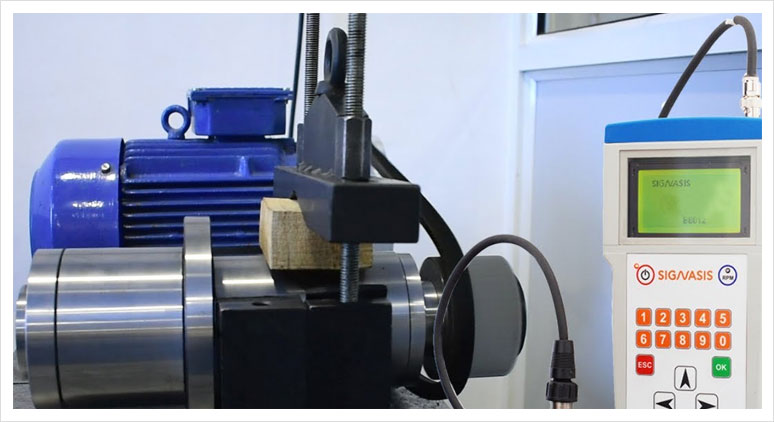

Field Balancing

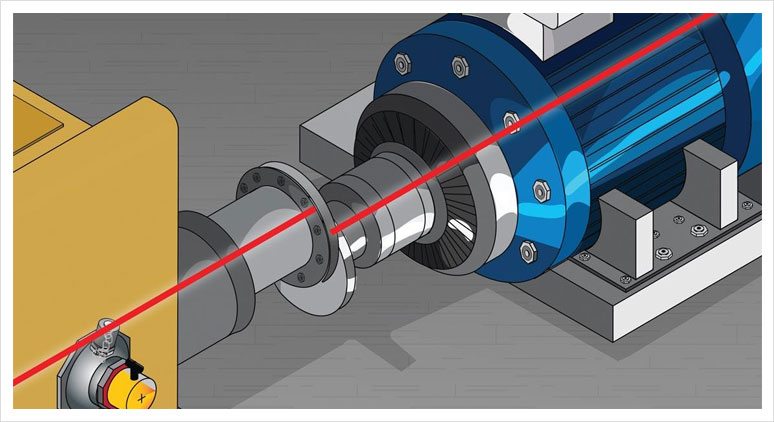

Shaft Alignment / Laser Alignment

Motor Current Analysis

Partial Discharge (PD) Testing

Oil Analysis

The concept of analysing an oil sample from a machine or component is identical to that taking a blood sample from a person, the results determine the health status of the unit.

By analyzing a sample of used engine oil, we can determine the amount of contamination, the wear rates and overall condition of the engine. The real benefit of an oil analysis is that it acts as an early warning system and alert the potential problems before they become an equipment failure.

Key Benefits of the ‘AIIPL’ Service Solution

We would be glad to extend our services to your esteemed organization. Our reputation and experience in this industry would be an added advantage for us to provide you quality service and support.